Specifications

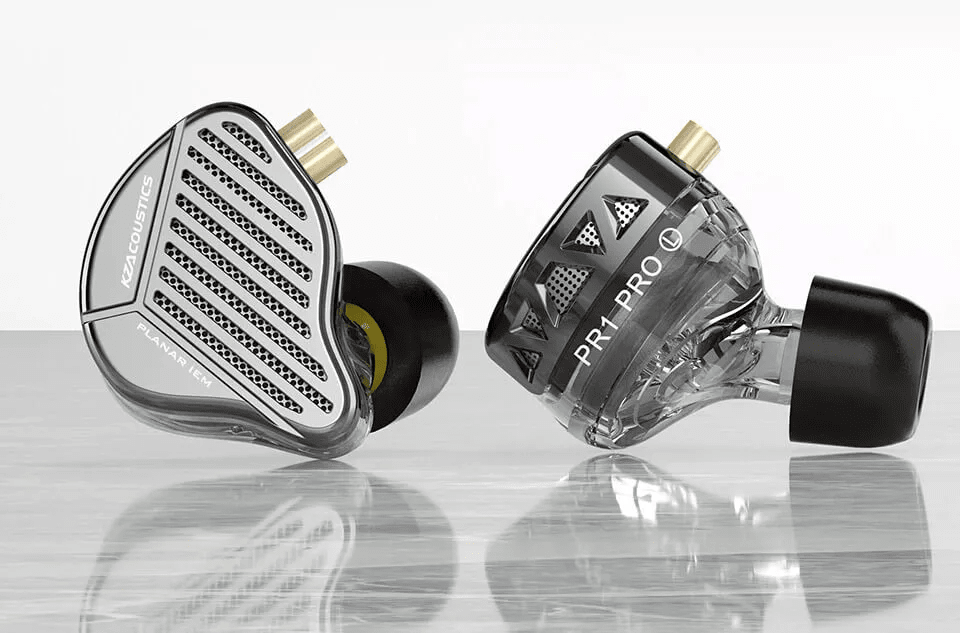

- Product model KZ PR1 Pro

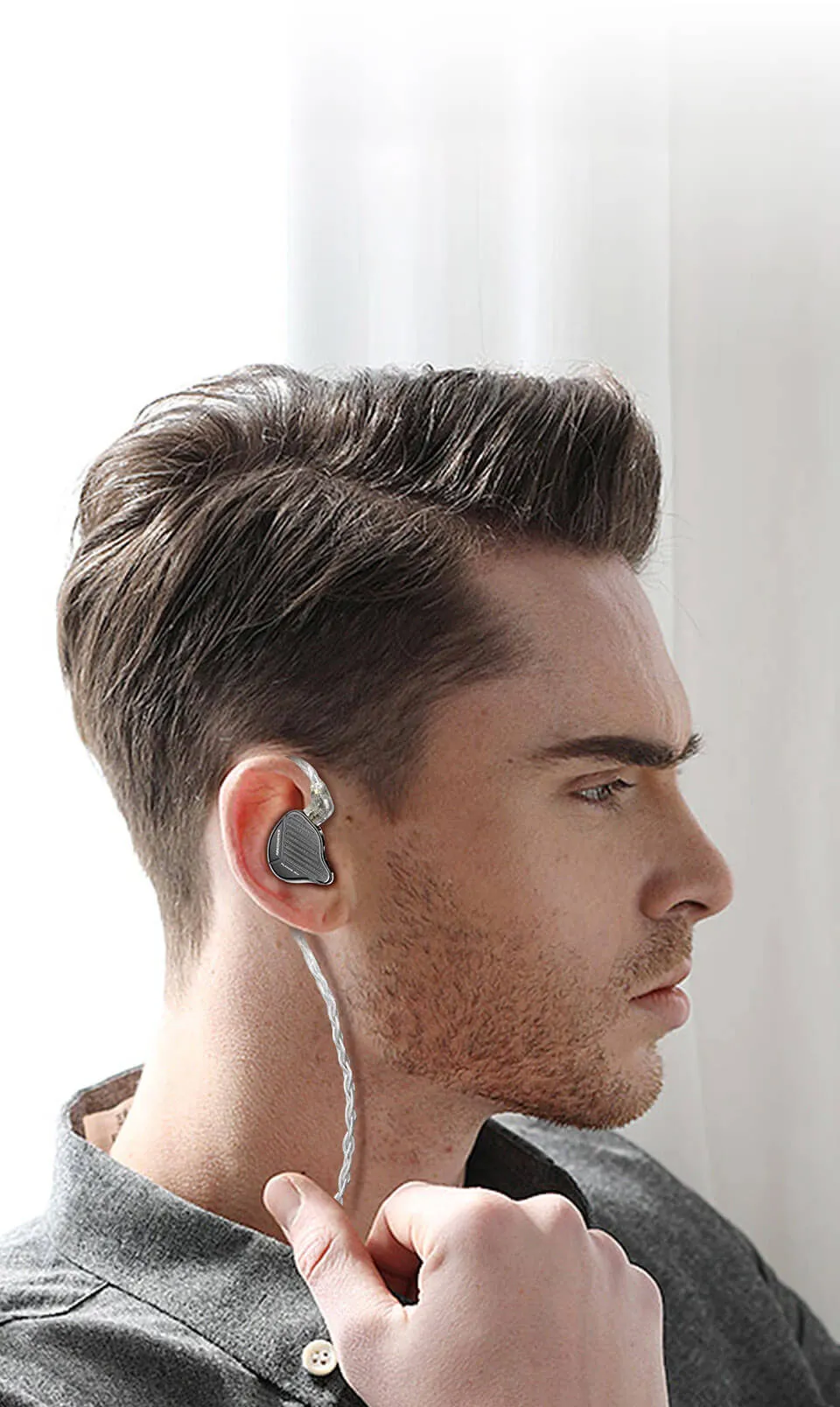

- Wearing type In-ear

- Impedance 16±3Ω

- Sensitivity 100±3dB

- Frequency 20-40000Hz

- Plug type 3.5mm

- Pin Type 0.75mm C Pin

- Cable length 120+5cm

- Cable Type Standard 8-strand braided silver-plated upgrade cable

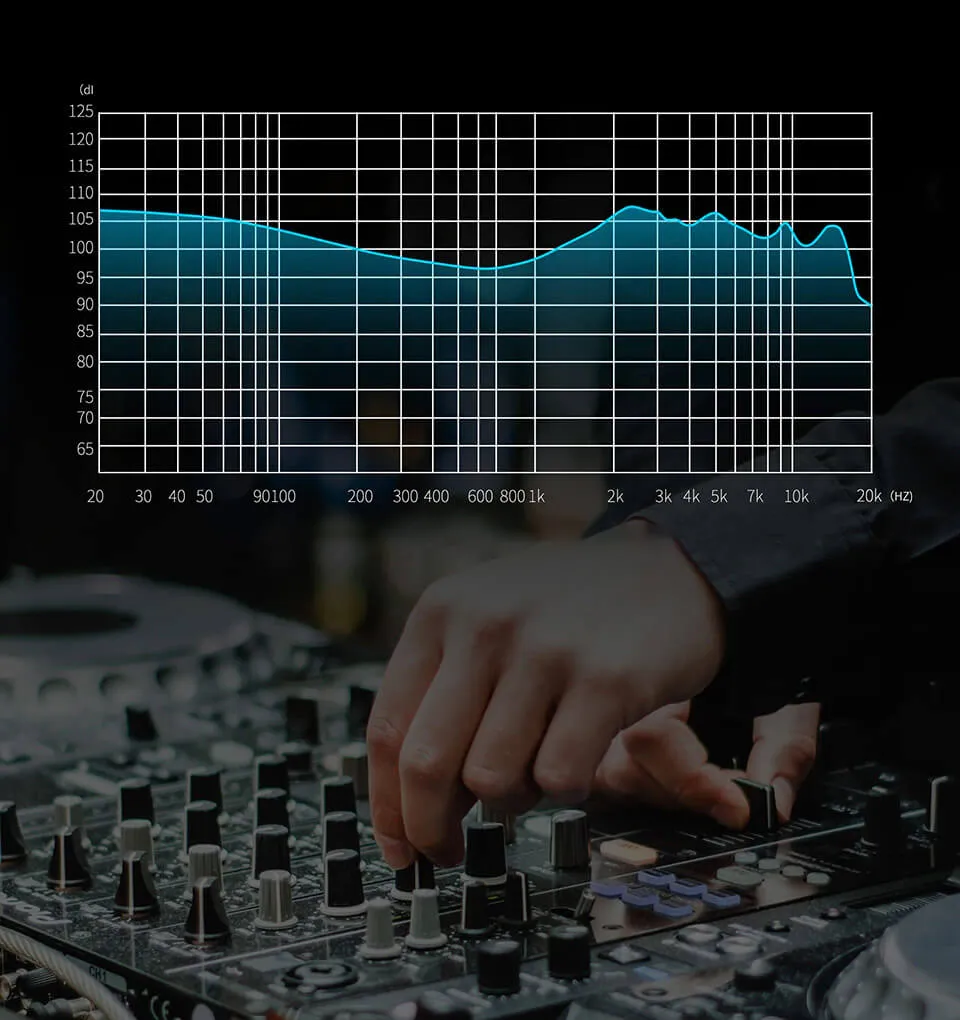

Newly upgraded 13.2mm planar unit

Note: In acoustic theory, when the sensitivity of the earphone is increased by 6dB, its performance is doubled. Compared with KZ PR1, the sensitivity of KZ PR1 Pro is increased by more than 3dB at 1kHz, so its performance increased by 50% around.

-

Higher sensitivity brings wider equipment compatibility and requires less input power.

-

High sensitivity is not expected to be achieved through simple tuning, which requires very precise component technology and high magnetic flux to the magnetic circuit design.

-

With the same input power and volume, the distortion rate of highly sensitive headphones is much lower than that of products with low sensitivity. It can easily show high-quality sound at a reasonable listening volume without fully loading.

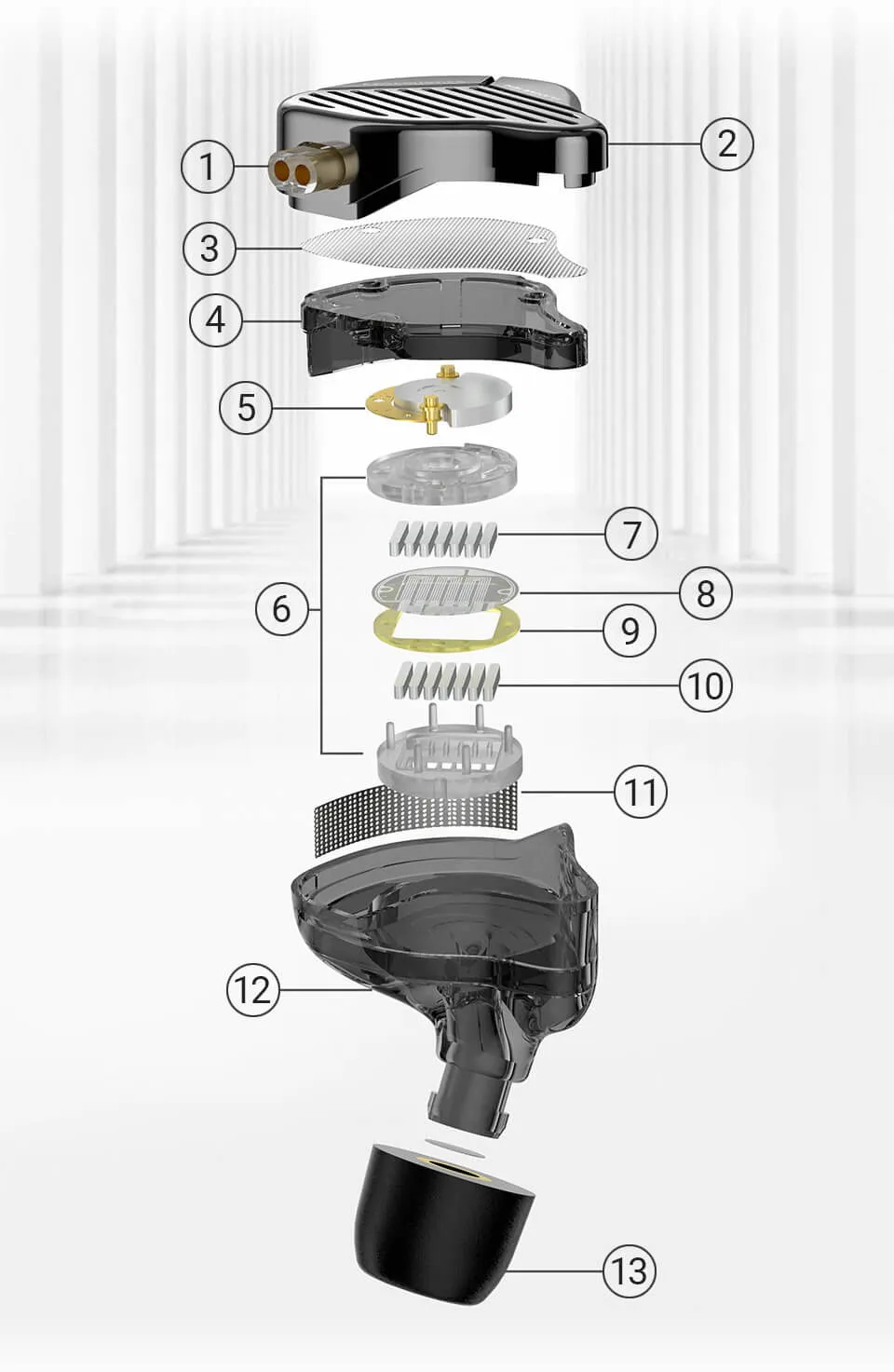

What is the real planar unit?

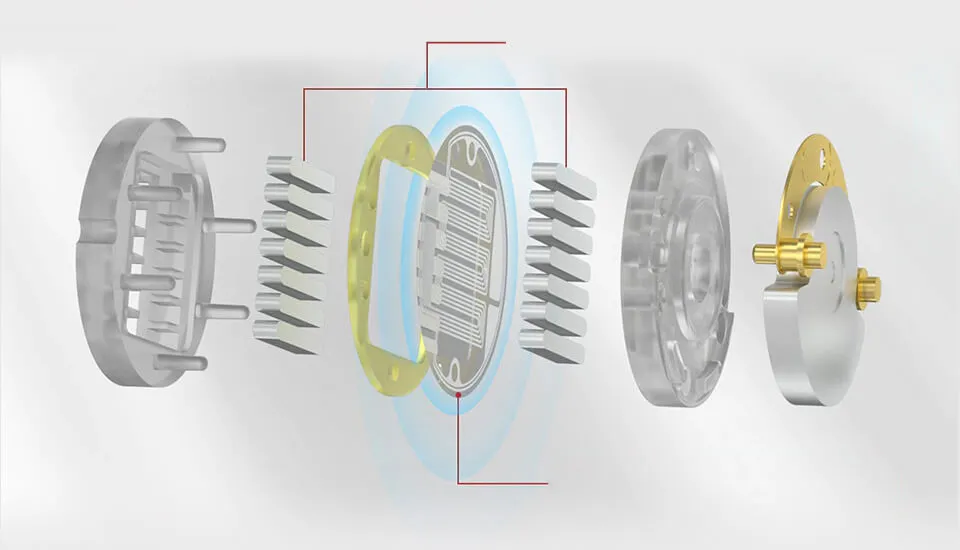

2. ln terms of product material, the most expensive material for manufacturing planar units is the diaphragm, and the thickness of this diaphragm is only 2-8 microns on average. The main reason for making this diaphragm expensive is that the circuit is to be plated on the diaphragm with a silver plating process on such a thin diaphragm, and the precision of the circuit needs to be controlled within 2 microns. Therefore, it is easy to have a high scrap rate in the production process. Another is the planar unit’s magnetic circuit system is very complex. The traditional dynamic unit and balanced armature unit are generally built-in only 1-2 magnets, while the planar unit’s average is starting design to 14 magnets. Of course, this number is far greater than the dynamic and balanced armature units. The advantages are very obvious. It brings a powerful resolution and wide sound field for the planar unit.

3. From the manufacturing process, because the number of parts used is much higher than the dynamic and balanced armature unit, and the production process is made of strict precision requirements than the former, the manufacturing of planar units is very complex. Compared to the production process of dynamic and balanced armature units, planar units have additional processes such as diaphragm shaping, diaphragm secondary pressing, magnetic circuit calibration, connection impedance testing, etc. These will make the traditional dynamic and balanced armature unit manufacturers helpless.

A combination of the above three aspects constitutes the main reason that determines the price of the planar unit is much higher than the dynamic and balanced armature units. However, its excellent acoustic performance is also destined to be the hobby of a few people positioned in the high-end Hi-Fi market.

Original Product Design Intention

Ergonomic + Unique Innovative Hi-Fi Style Design

Excellent detail restoration to present high-fidelity music

Personalized interface design

Standard 8-strand braided silver-plated upgrade cable

Reviews

There are no reviews yet.